What is the OSHA 1910.147 Standard?

By definition, the OSHA 1910.147 Standard covers the servicing and maintenance of machines and equipment in which the unexpected energization or startup of the machines or equipment, or release of stored energy, could harm employees. This standard establishes minimum performance requirements for the control of such hazardous energy. In simple English, this is the OSHA Standard that defines the requirement for LOTO Procedures in the US. Or as we like to call it, LOTOTO - Lock Out, Tag Out, Try Out!

The OSHA 1910.147 Standard is made up of different parts which must all be met to meet the standard requirement. The part that relates to padlocks and lockout devices is the 1910.147(c)(5), and the aim of this article is to break down the intricacies of this part to make the implication of your LOTOTO procedure as simple as possible.

The 5 OSHA requirements for Lockout Padlocks

1.Durable

OSHA 1910.147(c)(5)(ii)(A) is all about ensuring the durability of the padlocks and devices used. This doesn't necessarily mean using padlocks made with the strongest material however, as it is more important to use padlocks withstanding of the environment, they are going to be used in.

Laminated steel padlocks are strong and durable, although should be avoided at all costs for LOTOTO-use as they only have up to 400 combinations of key, meaning that there is a high risk of there being 2 of the same padlocks, and key for that matter, on your site. This leaves you with two available materials for your safety padlocks: Aluminum and Nylon.

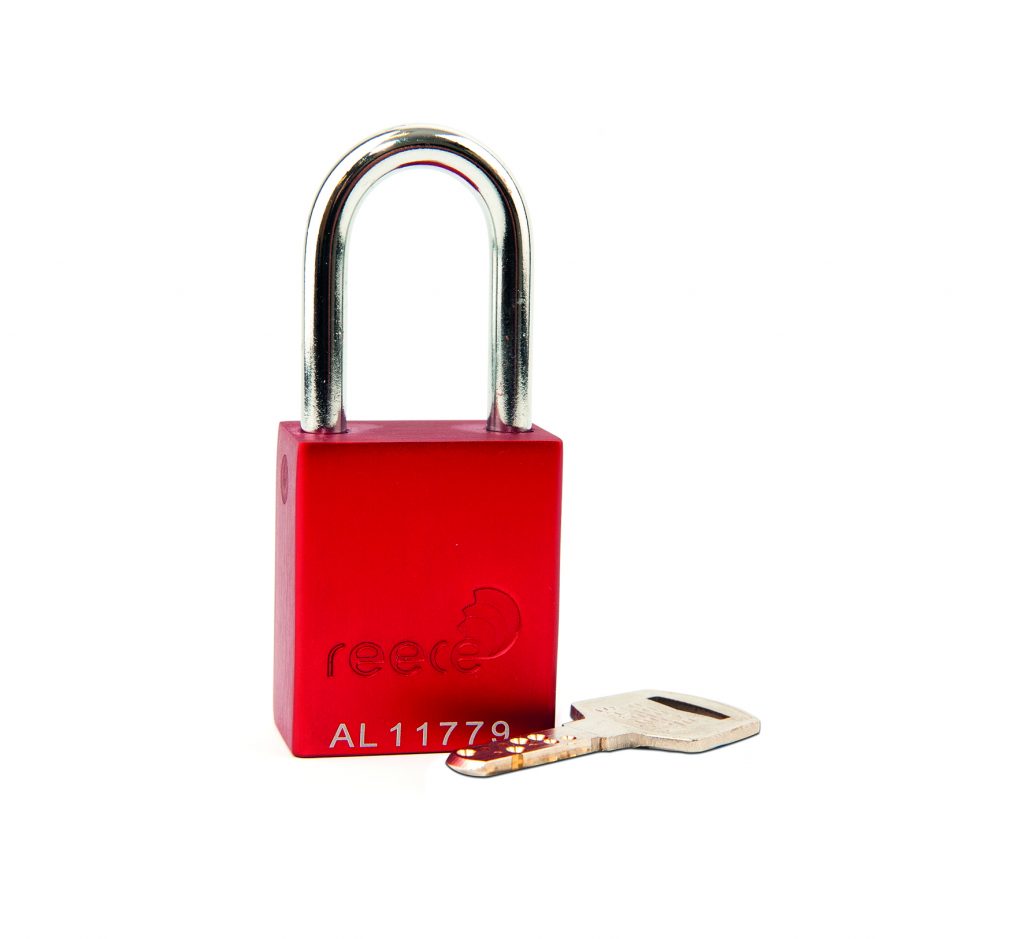

Aluminum padlocks are made from durable, solid aluminum with a steel shackle and have an anodized finish. Our Aluminum padlocks have high-security cylinders with over 20,000 key combinations meaning it is much more suitable solution for LOTOTO. Aluminum is a lightweight, corrosion-resistant material that does not rust. Aluminum is also non-magnetic and non-sparking. This makes it a good material for safety locks as they are durable, can be used in outdoor environments, and there is no risk of explosion from sparks reacting with fumes.

Nylon padlocks are made from Nylon plastic with a steel shackle. They too have high-security cylinders with over 20,000 key combinations. Nylon plastic shares all of the same properties as an aluminum padlock but is not as strong as aluminum, however this does not mean they are not suitable LOTOTO. Nylon body padlocks are non-conductive, meaning that in some environments they are more durable than aluminum. They are also a highly cost-effective solution for LOTOTO.

2. Substantial

OSHA 1910.147(c)(5)(ii)(C) ensures that lockout and tagout devices are substantial. For padlocks and lockout devices the requirement is met if the device is strong enough to prevent removal without the use of excessive force or unusual techniques such as bolt cutters or any other metal-cutting tools. Steel shackled padlocks obviously fulfill and exceed this requirement.

On a side note, for tagout devices, they must meet a 50lb minimum unlocking-strength requirement, be non-reusable, attachable by hand, in a self-locking manor, such as an environment-tolerant nylon cable tie. This is an important part of the standard that can be often overlooked. Tags that meet this requirement can be identified by having a brass eyelet, which reinforces the attachment point. The characteristic of an 'environment-tolerant nylon cable tie' remains vague and a method of ensuring this standard is met is through the use of car seals as an alternative.

3. Standardization

Part (c)(5(ii)(B) sets out the requirement for lockout and tagout devices to be standardized within the facility. The criterion for lockout device standardization is color, shape, or size, and for tagout devices, print and format.

There can be a misconception in industry that brand must be incorporated into this, this is false and is down to a customer's preference. For example, the 2 padlocks in Picture 1, could be used within the same facility LOTOTO procedure and still fully complies with this part of the standard. This can be a source of cost-saving for health and safety professionals by identifying more cost-effective manufacturers.

4. Identifiable

For lockout devices and tagout devices to comply with the OSHA 1910.147 Standard, they must identify the employee applying the device, as described by part (c)(5)(ii)(D). There are various methods that this standard can be fulfilled. The obvious answer is for the name of the employee to be handwritten onto the lockout device; however, this can present risks. Labels can fade and pen can wipe off, with it very difficult to fulfill the standardization requirement (as mentioned above) with this method. This can leave businesses and departments at risk of falling liable in the event of an incident.

Industry good practice is to engrave padlocks, with either the name or an employee identification number onto the padlock. This ensures that lockout devices will remain identifiable. Industry best-practice is for the safety padlocks to be color coded accordingly to criteria, such as department owner, (i.e. Operations Isolation Padlocks) or authority (e.g. Black = Senior Authorized Person Lockout device).

This part of the standard is to promote accountability for the employees involved with work on the lockout and can also be referred back to part (e)(3)(ii), which ensures that the employee who attached the lockout device must be the one to remove it.

5. Exclusive for Safety

Finally, under the OSHA 1910.147 Standard, Lockout padlocks should only be used to regulate potentially dangerous energy - no other purpose.

Key Considerations

Once you have chosen the padlock that meets the needs of your lockout procedure you must consider the key system you need for your lockout program. There are 3 different types of key systems.

Keyed to differ Padlocks. Each padlock can only be unlocked by a dedicated key and can’t match other padlocks. It’s the ideal lockout solution if an employee commonly applies a single lock.

Keyed Alike Padlocks.All safety padlocks within a designated group have the same key. It’s commonly used by maintenance personnel in charge of several machines or isolation points to save them from carrying multiple different keys.

Masterkeyed Padlocks.Has a master key specifically configured to open different padlocks, whether keyed differently or keyed alike—ideal LOTO padlock system solution when dealing with large teams. It must be remembered that this can present a risk of a Lockout system breach should this Master key fall into the wrong hands.

US

US UK

UK